Silicone molds: technology that shapes your products perfectly

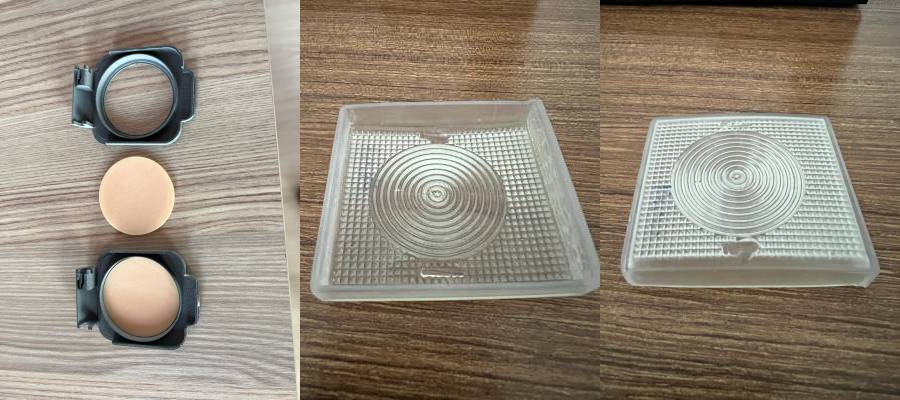

Silicone molding, which is one of our services, is a technology that allows you to mold products with perfection.

Nowadays, in industrial production and design processes, the perfect shaping of products and the achievement of high-quality results are crucial for success. In this process, silicone mold technology proves to be an outstanding and preferred method. Silicone molding is an innovative method commonly used in industrial applications that enables rapid, precise and repeatable manufacturing of products.

What is silicone molds?

Silicone molding is a copying process that involves injecting silicone rubber material using a master mold. This method creates a detailed copy of the original product. The silicone molding process is preferred in many industries due to its advantages such as design freedom, high precision, low cost and short production times.

Advantages of silicone molding

High precision: Silicone mold parts can precisely replicate even fine details and complex shapes of products. In this way, high quality results are achieved.

Low Cost: Silicone molds are more economical than other molding methods. The silicone material used in mold making is ideal for long-term use as it is durable and long-lasting.

Fast Production: Silicone molds allow for fast and repeatable production. This is an extremely important advantage for mass production.

Design freedom: With silicone molding, almost any design can be freely applied. It's easy to make changes or create variations on products.

Compatibility with various materials: Silicone mold part is compatible with various materials. In this way, it offers an ideal way to produce various products.

Where is silicone molding used?

Silicone molds are widely used in various industries. It is particularly preferred in the following areas:

Automotive: Silicone casting is used in many areas of the automotive industry, from prototype production to spare parts production.

Architecture and Construction: Silicone mold parts provide aesthetic and functional solutions for building elements and architectural details.

Model making and toys: In model making and the toy industry, the silicone molding process is preferred for mass production.

Electronics and household appliances: Silicone molding is used for protective covers or parts of electronic devices.

Silicone molding is a technology that enables rapid and precise manufacturing of products and is often preferred in industrial applications due to its advantages. Due to its high quality, low cost and freedom of design, it is becoming an indispensable production method for companies. You can also evaluate the silicone molding process to increase the quality in the production processes of your products and gain a competitive advantage.

If you are looking for silicone molding services, you can contact our team of experts and benefit from our solutions tailored to your needs. Contact us today for quality and fast production!

RIM technology (REACTION INJECTION MOLDING)

What is reaction injection molding (RIM)? Advantages and industrial areas of application

Reaction injection molding (RIM) is one of the fastest growing plastic injection molding processes today. This process enables the production of complex and durable plastic parts. In this article, we explore what RIM is, what benefits it offers, and its uses in various industries.

What is reaction injection molding (RIM)?

RIM is a low-pressure molding process for two-component liquid polymers such as high-performance polyurethane or polyurethane resins. Two liquid components are injected into the mold using a coupling reagent. Through the chemical reaction, liquid polymers in the mold take on the desired shape and solidify. The RIM process ensures that the products have high strength, low weight and complex geometries.

What are the advantages?

- Fast Production:RIM speeds up mass production by shortening molding time. This helps companies stay competitive.

- Lightweight and Strong Parts:Parts made with RIM are lightweight, yet strong and durable. This property is a great advantage, especially for applications in the automotive and aviation industries.

- Low production costs:Since RIM is a low-pressure molding process, the cost of the molds is lower. In addition, labor costs are reduced thanks to the automation of the process.

- Possibility of complex geometries:RIM facilitates the production of complex designs. Parts with difficult-to-access interiors can be easily manufactured thanks to RIM.

Industrial areas of application

- Automotive industry:In the automotive industry, many parts such as interior and exterior trim parts of vehicles, bumpers and air intake ducts are manufactured using the RIM method. Its low weight and easy implementation of complex designs make RIM a preferred manufacturing method in the automotive industry.

- Medical Devices:Medical devices require lightweight and durable parts manufactured using the RIM method. RIM is the ideal solution for medical devices such as cannula caps, surgical instruments and wheelchair parts.

- Electronics Industry:RIM is used in the external parts and housings of electronic devices. Their lightweight and durable structures offer significant advantages in the manufacture of products such as portable devices and telecommunications devices.

Reaction Injection Molding (RIM) is a method that allows the production of complex and durable plastic parts by injecting polyurethane or other reactive polymers into molds using numerical computer control. It is a preferred technology in many industries due to its advantages such as rapid production, manufacturing of lightweight and strong parts, and low cost. Its use is increasing in various fields such as automotive, medical devices and electronics, and it is predicted that the importance and prevalence of this method will increase in the future.